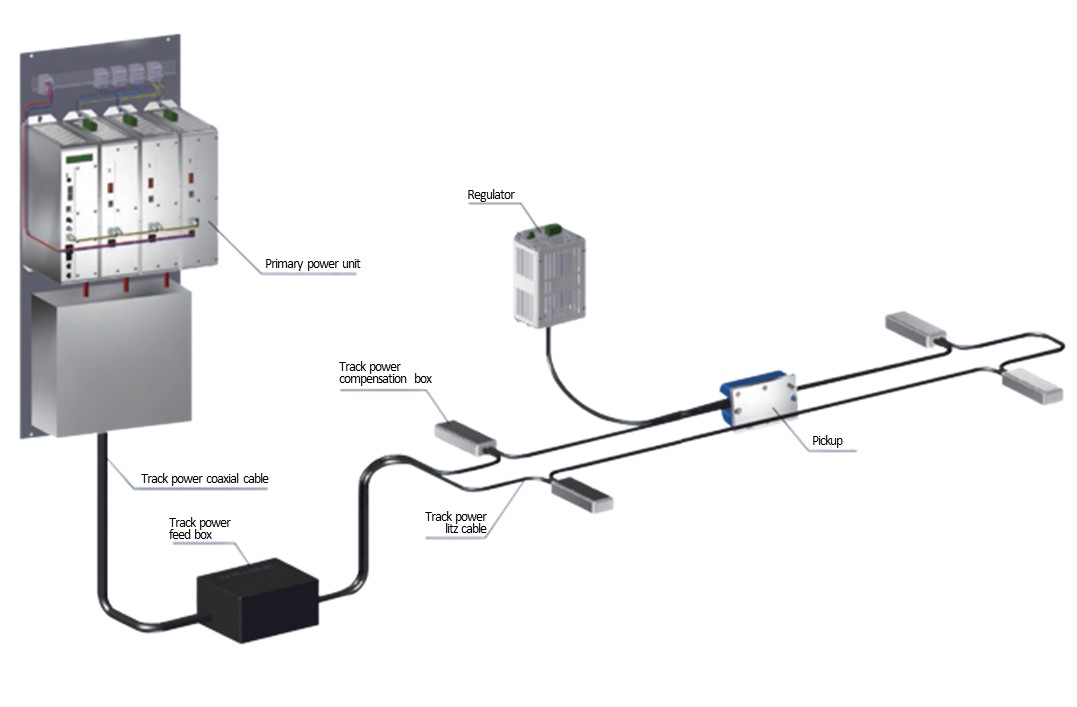

Contactless Trolley System

The contactless trolley system is a power supply system that utilizes the principle of electromagnetic induction to extract power by converting the magnetic flux generated by the trolley line or Litz cable to the faucet coil of the pickup. It enables a safe and clean power supply to a line of moving devices such as transporters used in factories, etc.

Features

Zero dust:

It can be used in a clean environment as there is no generation of grinding dust caused by contact movement.

Reduced maintenance costs:

The collector of contact power supply wears out and needs to be replaced, but since it is non-contact, there is no need to replace the collector.

Low noise:

No contact noise is generated by the contact movement of the main body and the collector arm of the contact feeder.